- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

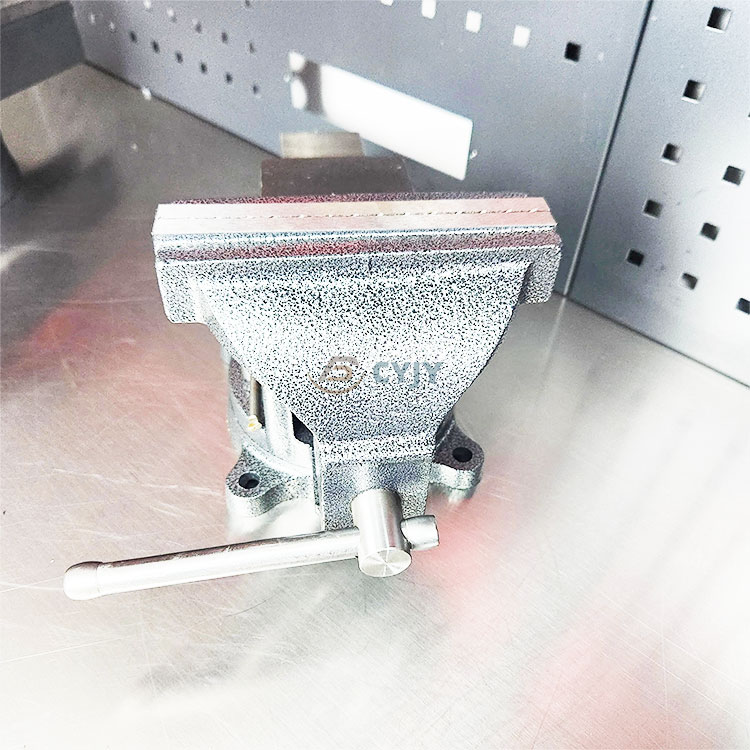

China Bench Vise Manufacturers, Suppliers, Factory

CYJY is a factory-type tool cabinet and bench vise supplier with over 26 years of experience in developing, manufacturing and selling tool cabinets, garage cabinets, tool benches and bench vises. The main function of a bench vise is to firmly fix the work piece on the workbench for processing, repair or other operations. By using a bench vise, you can ensure that the work piece remains stable during processing, thereby improving work efficiency and processing accuracy.

What is the main purpose of a bench vise?

Bench vise, as a common fixture for clamping workpieces, has a wide range of main uses and is very important. The following is an overview of the main uses of bench vise:

1. Clamping and fixing workpieces:

Bench vise can firmly clamp workpieces of various shapes and sizes, keeping them stable and motionless on the workbench. This is the basis for machining, assembly, debugging and other processes, ensuring that the workpiece will not move or deform during the machining process.

2. Auxiliary processing operations:

In mechanical processing jobs such as benchwork, lathe work, and milling, bench vise is often used to clamp workpieces for marking, sawing, filing, drilling, reaming, reaming, tapping and other operations. It provides a stable support point, making the machining process more precise and efficient.

Ensure machining accuracy:

Because the bench vise can accurately position and clamp the workpiece, it helps to ensure machining accuracy. This is particularly important in precision machining because it directly affects the quality and performance of the product.

3. Improve work efficiency:

Using a bench vise can save a lot of time and energy. It simplifies the clamping process of the workpiece and enables workers to start machining operations faster. At the same time, since the workpiece is firmly clamped, vibration and shaking during processing are also minimized, thereby improving work efficiency.

Protect workpieces and equipment:

The bench vise can prevent the workpiece from being damaged due to movement or deformation during processing. In addition, it can protect processing equipment from damage or wear caused by unstable workpieces.

4. Adapt to a variety of working environments:

The bench vise has a variety of types and specifications to adapt to different working environments and processing needs. Whether it is a small workshop or a large factory, you can find a bench vise that suits its needs.

In summary, the bench vise plays a vital role in machining, assembly, and debugging processes. It can not only clamp and fix the workpiece and assist in machining operations, but also ensure machining accuracy, improve work efficiency, and protect workpieces and equipment. Therefore, in the field of machining, the bench vise is an indispensable and important tool.

Advantages of bench vise

The benefits of a bench vise (commonly known as a vise or a vice) are numerous and important in a variety of industrial and DIY settings. Here are some of the main benefits:

1. Stability and safety:

A bench vise provides a stable and secure platform for clamping a workpiece. This ensures that the workpiece remains stationary during operation, reducing the risk of accidents and errors.

2. Versatility:

Bench vises can accommodate workpieces of various sizes and shapes. With adjustable jaws and clamping mechanisms, they can be used for a variety of tasks such as cutting, filing, drilling, and more.

Precision and accuracy:

By firmly clamping the workpiece, a bench vise allows for more precise and accurate operations. This is especially important in industries that require high precision, such as machining, woodworking, and metalworking.

3. Efficiency:

A bench vise simplifies the clamping process, saving time and effort. It enables workers to clamp the workpiece quickly and easily, so they can focus on the task at hand instead of struggling with the clamping process.

4. Durability:

Bench vises are made of high-quality materials to withstand frequent use and abuse. They can be used for years, providing a reliable and long-lasting solution, even in demanding environments.

Cost-effectiveness:

Considering their versatility, durability, and precision, bench vises are an excellent value for money. They are a cost-effective investment that can pay for itself over time through increased efficiency and accuracy.

5. Adaptability:

Bench vises can be adapted to a variety of workstations and setups. They can be mounted on a workbench, table, or even a wall, providing flexibility in where and how they can be used.

6. Ease of Use:

Even someone with limited experience can quickly learn how to use a bench vise. The simple and intuitive design makes clamping and releasing workpieces easy, allowing even beginners to achieve professional-grade results.

In summary, the advantages of a bench vise make it an indispensable tool for anyone involved in an industrial or DIY project that requires clamping a workpiece. Its stability, versatility, precision, efficiency, durability, cost-effectiveness, adaptability, and ease of use make it a valuable addition to any workspace.

How to use a bench vise?

When using a bench vise, you need to follow certain steps and precautions to ensure that the workpiece is clamped safely and effectively. The following are detailed steps and precautions on how to use a bench vise:

Steps

1. Prepare tools and materials:

Make sure that the bench vise, screws (usually included when purchasing the bench vise), workbench, etc. are all available.

If necessary, prepare tools that may be used for installation, such as electric drills, adjustable wrenches, etc.

2. Install the bench vise:

Clean the workbench or the slot on the workbench to ensure that it is clean and free of debris.

Place the bench vise in the desired position and fix it to the workbench with screws. Make sure the bench vise is firmly fixed to prevent it from moving or loosening during use.

When installing, make sure that part of the jaws of the fixed jaw body is outside the edge of the vise so that the edge of the vise is not obstructed when clamping long strips of workpieces.

3. Adjust the jaws:

Adjust the width and position of the jaws according to the shape and size of the workpiece.

Make sure the jaws fit the workpiece tightly to prevent the workpiece from moving during processing.

4. Clamp the workpiece:

Place the workpiece in the center of the jaws to ensure that the workpiece is stable and will not slip.

Use the handle to rotate the screw to move the movable jaw body relative to the fixed jaw body to clamp the workpiece.

When clamping the workpiece, it should be properly tight. Too loose will cause the clamped object to fall, and too tight may damage the object. Only use the hand plate to tighten the handle, and do not use other tools to increase the force.

5. Perform processing operations:

After clamping the workpiece, you can perform drilling, cutting, filing and other operations.

Pay attention to safety during processing to avoid workpiece flying out or hand injuries.

6. Loosen the jaws and remove the workpiece:

After completing the processing, rotate the handle to loosen the jaws.

Carefully remove the workpiece from the jaws to avoid damaging the workpiece or the jaws.

- View as

Large Bench Vise

Large Bench Vise is an important clamping tool, which is widely used in metal processing, wood processing, plastic processing and other occasions that require stable clamping of objects. Large Bench Vise is usually made of high-strength, corrosion-resistant materials to ensure that it has a long service life during use. Large Bench Vise can be used in a variety of processing occasions such as metal cutting, riveting, welding, drilling, grinding, etc. It is one of the indispensable tools in the fields of metal processing, wood processing, etc.

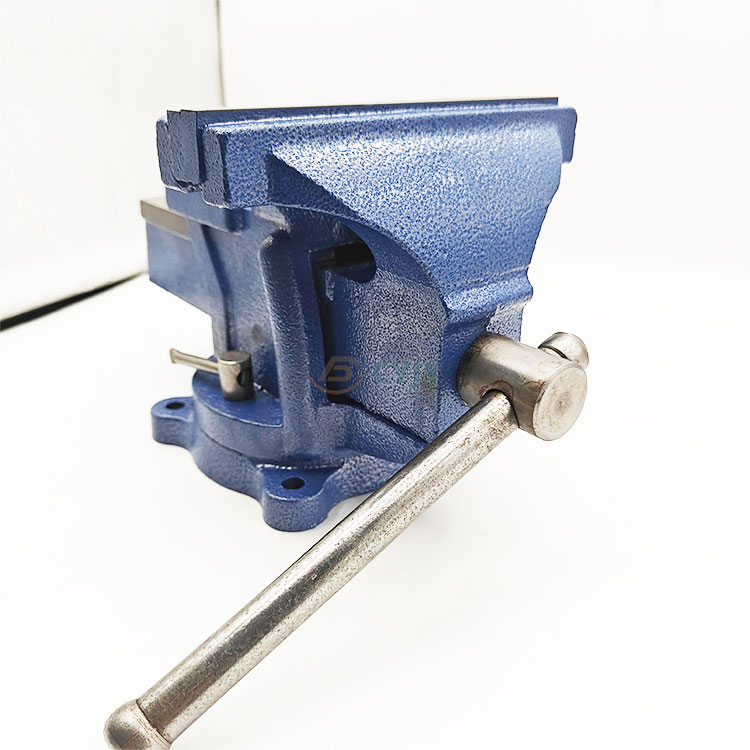

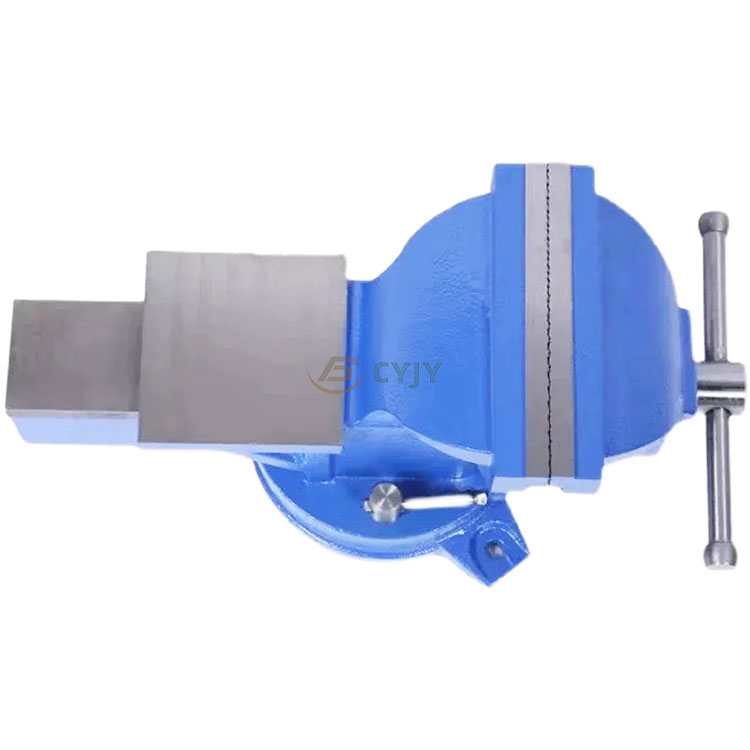

Read MoreSend InquiryIndustrial Bench Vise

An industrial bench vise is a tool designed to clamp and fix various materials (such as metal, wood, plastic, etc.) on a workbench to maintain its stability for processing, repair or other operations. Industrial bench vises are widely used in many scenarios such as machining, automobile repair, woodworking, DIY projects, etc.

Read MoreSend InquiryFrench Bench Vise

French bench vise, also known as French type bench vise, is a classic clamping tool, which is widely used in bench workshop and workpiece processing. The clamping force of French bench vise is relatively weak, but its clamping range is wide, which can meet the clamping needs of various workpieces.

Read MoreSend InquiryLight Bench Vise

A light bench vise is a clamping tool with fixed or movable jaws, usually installed on a workbench, used to clamp workpieces for processing, measurement, assembly, etc. Light bench vises are suitable for clamping various small workpieces and are an indispensable tool for benchwork, machine repair, assembly, etc.

Read MoreSend InquiryBench Vise Table

In order to improve the work efficiency of customers, CYJY provides Bench Vise Table for customers' convenience. By adjusting the screw of the vise, the Bench Vise Table can firmly clamp workpieces of different sizes and shapes to meet various processing needs. Bench vises table are usually made of high-strength materials such as cast aluminum or cast iron to ensure that they have sufficient stability and durability during use.

Read MoreSend InquiryHeavy Duty Bench Vise

Heavy duty bench vise is a new type of tool newly designed by CYJY. The main structure of heavy-duty bench vise is usually composed of clamp bed, jaws, spiral rod and other parts. These parts work together to ensure that the workpiece can be clamped stably and firmly. It is suitable for industries such as machining, woodworking, metalworking, printing, pipeline and lathe. In these industries, heavy-duty bench vise is often used to clamp workpieces of various shapes and sizes to ensure the smooth progress of the processing process.

Read MoreSend Inquiry